Fabrication

Fanello Industry’s fabrication and welding shop can simplify the process of bringing your product ideas and designs to realization. With multiple material processing options, our skilled team selects the right tools to create your project to your specifications.

Material Processing Equipment:

Trumpf 3030 (4.0 kW CO2)

- Thickness: .020” (.508mm) to .50" (12mm)

- Sheet Size: 5’ (1524mm) x 10’ (3048mm)

- Carbon, Stainless, Aluminum

Mazak Hyper Gear 612 4000W Laser

- Thickness: .020” (.508mm) to 1” (25mm)

- Sheet Size: 7’ (2133mm) x 12’ (3657mm)

- Carbon, Stainless, Aluminum

Safan B35T Press Brake

- 35 Ton electric

- CNC Controlled R, Y1, Y2, and X Axis

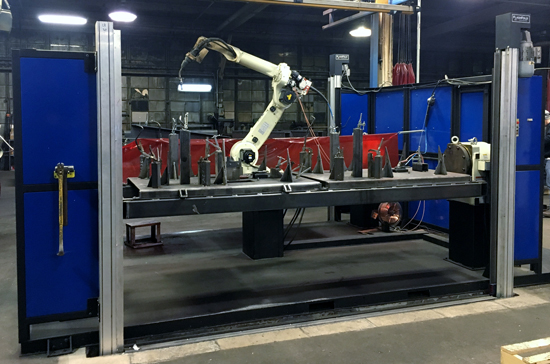

2 Fusion Arc 180L Robotic Welding System

- Cell Dimension 11' W x 15'L x 7'H

- 2 Tailstock Assemblies and Pedestals

2 Eaton Leonard CNC Tube Bender

- Model VB80

- Capable of bending 3.15" (80mm) diameter tubing

- CNC Hydraulic tube bending

Accupress Press Brake

- 250 Ton Hydraulic

- 144” (3658cm) Bed Length .250" (7mm) full length

- 63.75” (1620mm) at .375” (10mm) thickness

- CNC controlled backstop

Herr Voss Precision 4-High Leveler

- Thickness: .020” (.508mm) to .25” (6mm) cut

- Width: 68” (1727.2mm)

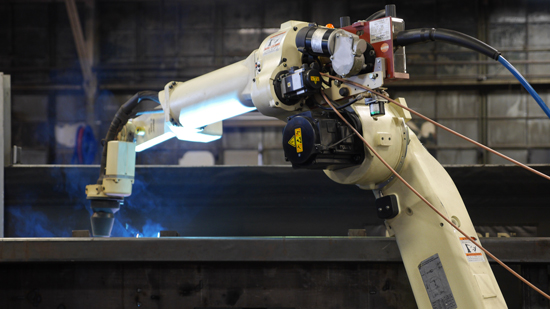

Assembly/Welding

- Tig

- Mig

- Stick Welding

- Aluminum Welding

- Robotic Weld Cells